Proper calibration is essential for ensuring a product’s longevity because it directly impacts the product’s performance, accuracy, and reliability over its operational lifespan. Calibration is the process of adjusting and fine-tuning a product’s measurements, settings, or parameters to align with established standards or reference values. This process plays a crucial role in maintaining the product’s functionality and preventing degradation, ultimately extending its longevity and usability. Here’s why proper calibration is so important for ensuring a product’s longevity: Accuracy and Precision: Calibration ensures that a product produces accurate and consistent results. For products that involve measurements or data collection, such as scientific instruments, medical devices, and manufacturing equipment, accuracy is critical. Inaccurate measurements can lead to faulty outcomes, incorrect decisions, or compromised product quality. Proper calibration guarantees that the product continues to deliver precise results over time, maintaining its effectiveness and reliability.

Regular calibration practices

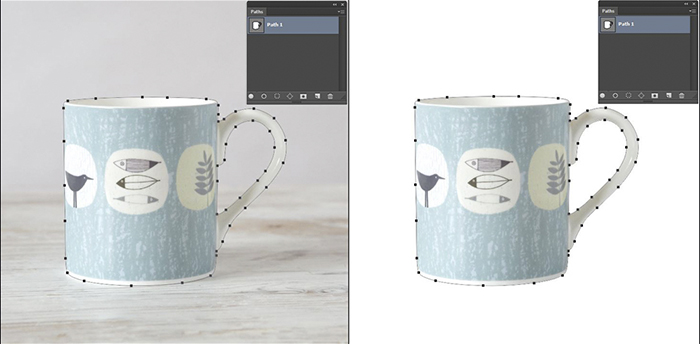

Manufacturers and operators can identify potential issues or irregularities before they escalate into more significant problems. This proactive approach allows for timely maintenance and adjustments, preventing sudden failures and breakdowns that could otherwise shorten the Clipping Path product’s lifespan. Regulatory Compliance: Many industries are subject to regulatory standards that mandate regular calibration. Adhering to these standards ensures that products meet specific performance and accuracy criteria. Regulatory compliance not only ensures product reliability but also guarantees safety and consistency in industries such as healthcare, aerospace, and manufacturing. Meeting regulatory requirements contributes to the product’s longevity by validating its ability to perform consistently and accurately. Cost-Efficiency: Calibrating a product at regular intervals can save costs in the long run. By identifying issues early on and addressing them through calibration and maintenance, companies can avoid expensive repairs or replacements that might arise from undetected problems.

A well-calibrated product not only performs

Well-calibrated products are less likely to experience sudden failures or erratic behavior, leading to lower operational costs and better resource utilization. In conclusion, proper calibration is integral to ensuring a product’s longevity by maintaining accuracy, optimizing performance, preventing degradation, facilitating timely maintenance, and ensuring regulatory compliance. A well-calibrated product not only performs consistently and accurately but also experiences reduced wear and tear, leading to extended usability and reliability. Regular calibration practices are an investment in the product’s overall lifespan, providing users with the confidence that their investment will deliver dependable results over time. enhancing a product’s reliability by minimizing errors, maintaining consistent performance, and instilling confidence in its users. Here’s how accurate calibration contributes to a product’s reliability: